At Straight Up Marine, we understand that every vessel has its own demands. From gyro stabilizer installations to electrical and hydraulic system servicing, our technicians bring hands-on experience with all major marine systems. As a certified Dometic dealer, we provide precise installations and maintenance for the industry’s leading stabilization systems — helping boat owners enjoy smoother, safer rides even in challenging conditions.

Nothing beats the comfort of stepping into a cool, climate-controlled cabin after a day in the sun, but that luxury depends entirely on proper marine climate control maintenance.

Your boat’s air conditioning system works harder than residential units, battling salt air, moisture, and constant motion while providing the comfort that makes extended time aboard truly enjoyable.

Unlike home AC systems that run seasonally, marine climate control maintenance requires year-round attention due to the harsh marine environment. Saltwater, humidity, and unique shipboard challenges mean your boat’s AC system needs specialized care to deliver reliable performance when you need it most.

Understanding Your Marine Climate System

Marine air conditioning systems typically use sea water for cooling, circulating it through condensers to remove heat from the refrigerant. This direct-exchange system is efficient but creates unique maintenance challenges. The constant exposure to saltwater means components face corrosion, marine growth, and scale or barnacle buildup that don’t affect land-based systems.

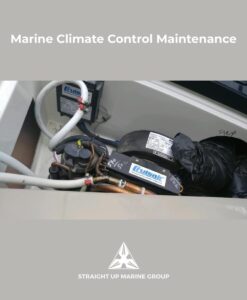

Most marine climate control maintenance focuses on three critical components: the evaporator (where refrigerant absorbs heat from cabin air), the compressor (which circulates refrigerant), and the condenser (where sea water removes heat from refrigerant). Understanding this flow helps identify where problems occur and what maintenance prevents them.

Monthly Marine Climate Control Maintenance

Monitor Water Flow: The most critical aspect of marine climate control maintenance is ensuring adequate seawater flow. Check the discharge water at your through-hull fitting every time you start the system. Strong, steady flow indicates healthy operation, while weak or intermittent discharge signals restriction that can damage the compressor.

Clean Air Filters: Marine environments are particularly hard on air filters. Salt air, deck spray, and engine fumes quickly clog filters, reducing efficiency and potentially damaging the evaporator. Clean or replace filters monthly during heavy use periods. Most systems have two filters: one at the return air grille and another at the evaporator unit.

Inspect The Sea Strainer Basket: The raw water intake strainer protects your system from debris and marine growth. Check it monthly, ensuring the stainless steel or plastic mesh isn’t corroded or clogged. Keep spare baskets aboard; the fine mesh erodes quickly in saltwater and failure can shut down your system completely.

Seasonal Marine Climate Control Maintenance

Spring Commissioning: Before boating season, conduct thorough marine climate control maintenance to ensure reliable summer operation. Inspect all hoses from seacock to discharge, looking for corrosion, cracks, or soft spots indicating impending failure. Check hose clamps; double clamp connections where possible for added security.

Test system operation by running complete cooling cycles, monitoring water discharge and listening for unusual noises. Spring is ideal for flushing condensate drains and inspecting drain pans for corrosion or blockage.

Mid-Season Service: During peak usage, increase marine climate control maintenance frequency. Weekly visual inspections can catch problems before they strand you in sweltering conditions. Pay attention to electrical connections, which corrode quickly in marine environments.

Fall Winterization: Proper winterization is crucial marine climate control maintenance in freezing climates. Drain the raw water system completely, starting from the seacock through the strainer, pump, and condenser. Use compressed air to ensure complete drainage, or flush with marine antifreeze rated for your climate.

Advanced Maintenance Tasks

Condenser Coil Cleaning: Scale buildup on condenser coils restricts water flow and reduces cooling efficiency. Professional marine climate control maintenance should include periodic coil cleaning with biodegradable acid solutions. This typically occurs every 2-5 years depending on water conditions and usage patterns.

Electrical System Inspection: Marine environments are particularly hard on electrical connections. Annual inspection of wiring, terminals, and control panels prevents failures that can be expensive and inconvenient. Look for corrosion, loose connections, and damaged insulation.

Troubleshooting Common Issues

Insufficient Cooling: Often indicates restricted water flow, dirty air filters, or refrigerant issues. Start with marine climate control maintenance basics; check water discharge, clean filters, and ensure adequate airflow around the unit.

System Short Cycling: When the AC turns on and off rapidly, it usually indicates high-pressure shut down due to insufficient water flow or overheating. Check the raw water system thoroughly, starting with the strainer and working through to the discharge.

Water Discharge Issues: No water discharge typically means pump failure, blocked intake, or closed seacock. Weak discharge often indicates restriction in the strainer, hoses, or condenser coils.

The Investment in Comfort

Proper marine climate control maintenance cost far less than emergency repairs or system replacement. A neglected system might last 3-5 years, while maintained units often provide 7-10 years of reliable service. The difference in operating costs, reliability, and comfort makes maintenance a clear investment in your boating enjoyment.

Failed hoses or through-hulls can sink boats, particularly when systems run unattended. This risk alone justifies careful attention to marine climate control maintenance, especially the raw water system components.

Professional vs. DIY Maintenance

Most marine climate control maintenance tests are within boat owner capabilities when following proper procedures. Monthly inspections, filter cleaning, and basic system checks require only basic tools and knowledge.

However, certain aspects require professional attention. Refrigerant system work requires EPA certification, and complex electrical troubleshooting may exceed typical owner capabilities. Annual professional inspection can catch developing problems before they become expensive failures.

Marine climate control maintenance isn’t just about comfort; it’s about reliable operation, system longevity, and safety. A well-maintained system provides years of trouble-free cooling, while neglect leads to expensive failures and uncomfortable conditions when you most want to enjoy your time on the water.

That marine environment demands more tension than land-based systems, but the investment and proper maintenance pays dividends and reliability, efficiency, and peace of mind. Stay cool on the water by staying on top of your marine climate control maintenance schedule.

This article provides general guidance for marine climate control maintenance. Always consult your system’s manual and qualified marine technicians for specific procedures and safety requirements.

Sources

- BoatUS – “Air Conditioning Maintenance For Your Boat”

- Southern Boating – “DIY Marine AC Maintenance Advice: How to Stay Cool on Board”

- Coastal Air Systems – “How Marine Air Conditioning Systems Work for Boats”

- Marine AC of Central Florida – “Marine Air Conditioning Maintenance: 5 Essential Tips”

- West Marine – “Selecting Air Conditioning for your Boat”